Charcoal briquette in the world of outdoor grilling and barbecuing, charcoal briquettes are a preferred choice for many, owing to their ability to burn longer and provide consistent heat. But what is the science behind their enduring burn time? This article delves into the manufacturing process, composition, and physical properties of charcoal briquettes to explain why they outlast their counterparts.

The Making of Charcoal Briquettes: A Blend of Science and Engineering

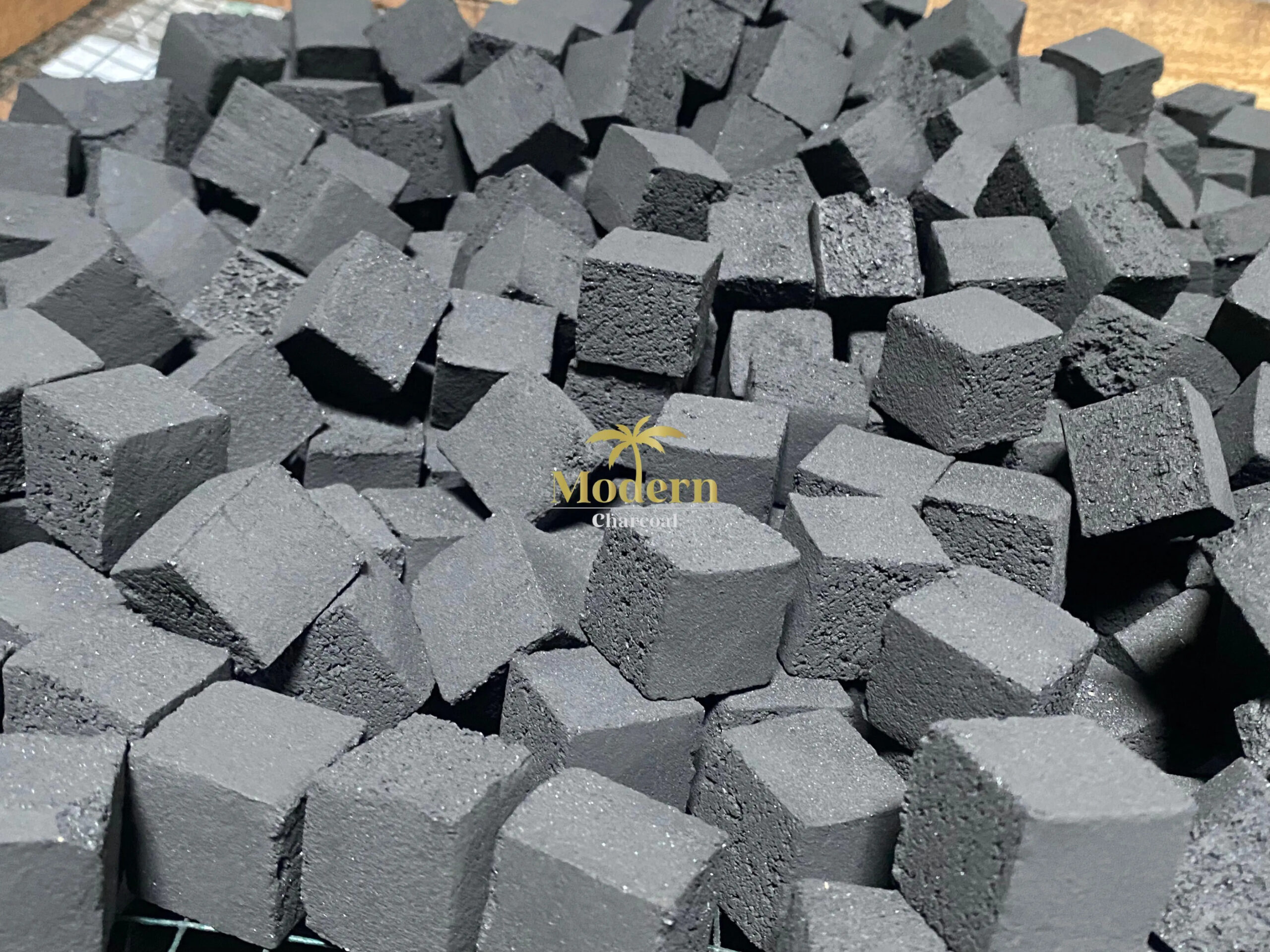

Charcoal briquettes are manufactured through a meticulous process that transforms wood by-products and other organic materials into a compact, energy-dense form. The process begins with carbonization, where raw materials are heated in an oxygen-limited environment, turning them into charcoal. This charcoal is then ground into a fine powder and mixed with binders such as starch, and sometimes additives that improve burn time, like sodium nitrate or borax. The mixture is compressed into uniform shapes and sizes, resulting in the briquettes we use in our grills.

Composition: The Key to Longevity

The composition of charcoal briquettes plays a pivotal role in their ability to burn longer. Unlike lump charcoal, which can vary in size and burn rate, briquettes are designed for a steady, controlled burn. The binders and additives not only hold the charcoal together but also regulate the burn rate. For instance, sodium nitrate acts as an oxidizer, ensuring a more consistent and longer burn by providing additional oxygen to the charcoal.

Physical Properties: Density and Uniformity

The physical properties of charcoal briquettes, notably their density and uniformity, contribute significantly to their long burning time. The compression process during manufacturing increases the density of the briquettes, meaning they have less surface area exposed to oxygen compared to lump charcoal. This reduced exposure slows down the combustion process, allowing briquettes to burn more slowly and steadily. Moreover, their uniform shape and size promote even heat distribution, further enhancing their efficiency and longevity.

Environmental Impact and Sustainability

While charcoal briquettes offer the advantage of a longer burn time, it’s important to consider their environmental impact. The production process, especially when not using sustainable wood sources, can contribute to deforestation and greenhouse gas emissions. However, many manufacturers are turning to sustainable practices, using recycled wood by-products and environmentally friendly binders, making charcoal briquettes a more eco-conscious choice for outdoor cooking. One of the most compelling reasons to choose coconut charcoal briquettes is their eco-friendliness. Unlike traditional wood charcoal or coal, coconut charcoal is made from a renewable resource that does not contribute to deforestation. Additionally, coconut trees are highly sustainable, producing coconuts throughout the year for up to 60 years, making the shells an ever-available byproduct.

Conclusion

The science behind the longer burn time of charcoal briquettes lies in their careful manufacturing process, precise composition, and specific physical properties. By understanding these factors, consumers can make informed choices about their outdoor cooking fuels, balancing efficiency, and environmental impact. As the barbecue season approaches, this knowledge empowers us to not only enjoy our grilling experiences but also appreciate the science that makes them possible.