In an era where the clamor for renewable energy sources is louder than ever, briquette manufacturing emerges as a beacon of hope for both environmental sustainability and energy efficiency. This method of producing combustible blocks from various organic materials not only presents an eco-friendly alternative to traditional fossil fuels but also offers a viable solution to managing agricultural and industrial waste. Through this article, we delve into the intricacies of briquette manufacturing, highlighting its processes, benefits, and its significant role in the global transition towards greener energy solutions.

Understanding Briquette Manufacturing

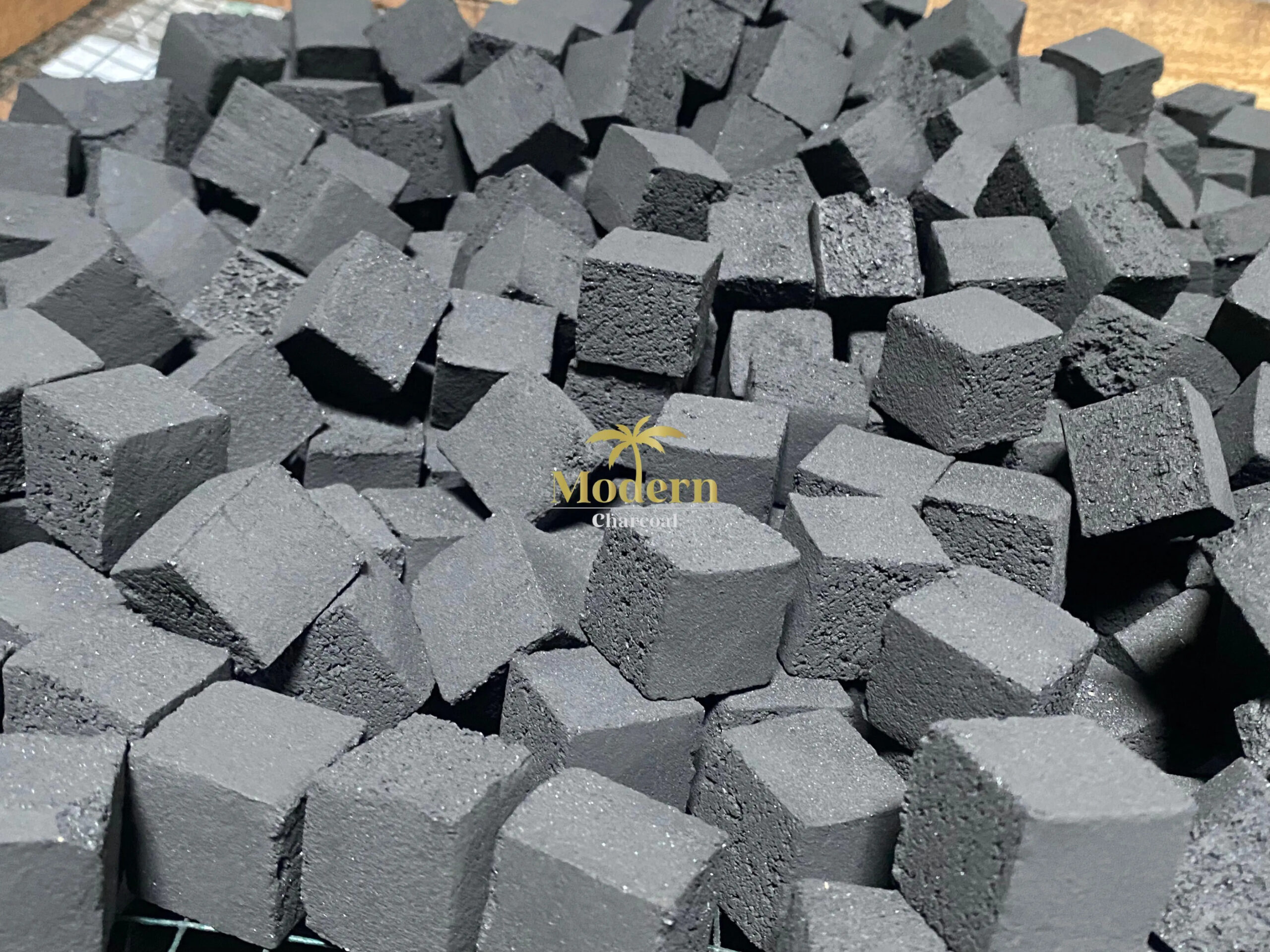

Briquette manufacturing involves the conversion of dry biomass into high-density fuel blocks through a series of processes. These biomass materials can range from agricultural residues like rice husks and sawdust to industrial waste and shredded paper. The process generally encompasses the collection of raw materials, drying, grinding, and then compressing the biomass under high pressure in a briquetting machine. The result is compact briquettes that are easy to store, transport, and use as fuel.

The Process Step by Step

1. Collection of Biomass:

The first step involves gathering suitable biomass materials. These are often by-products of agricultural processes or industrial waste that would otherwise contribute to pollution.

2. Drying:

Moisture content in the biomass is reduced, usually to below 15%, to ensure efficient combustion and to prevent mold growth in the briquettes.

3. Grinding:

The dried biomass is then ground into a fine powder. This increases the surface area, making it easier to bind the particles together during the compression phase.

4. Compression:

Using a briquetting machine, the powdered biomass is compressed under high pressure, transforming it into solid blocks. The pressure heat also acts as a binding agent, eliminating the need for additional binders.

5. Cooling and Packaging:

The hot briquettes are cooled and then packaged for storage or sale.

Environmental and Economic Benefits

The adoption of briquette manufacturing holds numerous advantages for the environment, economy, and society at large:

– Waste Reduction: By converting agricultural and industrial residues into valuable fuel, briquette manufacturing contributes significantly to waste management efforts.

– Carbon Footprint Mitigation: Briquettes produce fewer pollutants compared to coal and other fossil fuels, thereby reducing greenhouse gas emissions.

– Sustainable Energy Source: As a renewable energy source, briquettes ensure a continuous supply of fuel without depleting natural resources.

– Economic Advancement: This industry not only generates employment opportunities but also provides an additional revenue stream for farmers and businesses through the sale of waste materials.

– Energy Efficiency: Briquettes have a higher thermal value and lower moisture content than raw biomass, leading to more efficient burning and heat production.

The Road Ahead

Despite its numerous benefits, the widespread adoption of briquette manufacturing faces challenges, including the initial investment cost for machinery and the need for consumer awareness about this sustainable fuel option. However, with supportive policies, technological advancements, and increased environmental consciousness, briquette manufacturing is poised to play a pivotal role in the global shift towards renewable energy sources.

To find briquette manufacturers near you, consider the following steps:

Online Directories and Marketplaces: Websites like Alibaba, ThomasNet, and Made-in-China list manufacturers from around the world, including those in your region. You can filter your search by location to find briquette manufacturers near me.

Local Business Directories:

Check local business directories or chambers of commerce websites for listings of manufacturers in your area. These resources can provide contact information and possibly ratings or reviews.

Search Engines:

Use search engines to look for briquette manufacturers by including your location in the search terms, such as “briquette manufacturers near me” or “briquette suppliers in [Your City].”

Social Media and Forums:

Platforms like LinkedIn, Facebook, and specific forums related to renewable energy or grilling might have recommendations or advertisements from briquette manufacturers.

Trade Shows and Expos:

Attending local trade shows, expos, or fairs focused on renewable energy, grilling, or outdoor cooking can provide direct access to suppliers and manufacturers.

Referrals:

Ask for recommendations from friends, family, or businesses that use briquettes. Word-of-mouth can often lead you to reputable local suppliers.

In conclusion, briquette manufacturing not only stands out as an environmentally friendly alternative to conventional fuels but also exemplifies the potential of innovative technologies in achieving sustainable development goals. As we continue to confront the challenges of climate change and energy security, the promotion and expansion of the briquette manufacturing industry will undoubtedly contribute significantly to a cleaner, greener, and more sustainable future.