In an era where sustainability and eco-friendliness are more than just buzzwords, the quest for renewable energy sources and eco-conscious manufacturing processes has led to innovative solutions that echo the wisdom of ancient practices while addressing modern needs. Among these solutions, the art of crafting charcoal briquettes from natural ingredients stands out as a testament to human ingenuity in harnessing nature’s bounty for sustainable living.

The Essence of Charcoal Briquettes

Charcoal briquettes, commonly used for heating and cooking, offer a more sustainable and environmentally friendly alternative to traditional wood charcoal or fossil fuels. The process of making these briquettes from natural ingredients not only recycles organic waste but also produces a fuel source that is cleaner burning, with lower emissions of harmful pollutants.

Ingredients from Nature’s Pantry

The journey of making charcoal briquettes begins with the collection of biomass materials. This includes a wide range of organic waste such as sawdust, coconut shells, rice husks, bamboo scraps, and even dried leaves. These materials are abundant and often considered waste, making them an ideal choice for recycling into something of value.

Crafting the Briquettes: A Step-by-Step Process

1. Preparation of Biomass

The first step involves gathering and preparing the biomass. This process may include drying the materials to reduce moisture content, which ensures efficient carbonization later on.

2. Carbonization

Next, the prepared biomass is subjected to carbonization. This involves heating the materials in a controlled environment with limited oxygen. The process converts the biomass into charcoal, eliminating water and volatile compounds, and concentrating the carbon content.

3. Crushing and Mixing

The resulting charcoal is then crushed into a fine powder. Natural binders, such as starch from cassava, corn, or potatoes, are added to the charcoal powder. This mixture is crucial for shaping the briquettes and ensuring they hold together during use.

4. Shaping the Briquettes

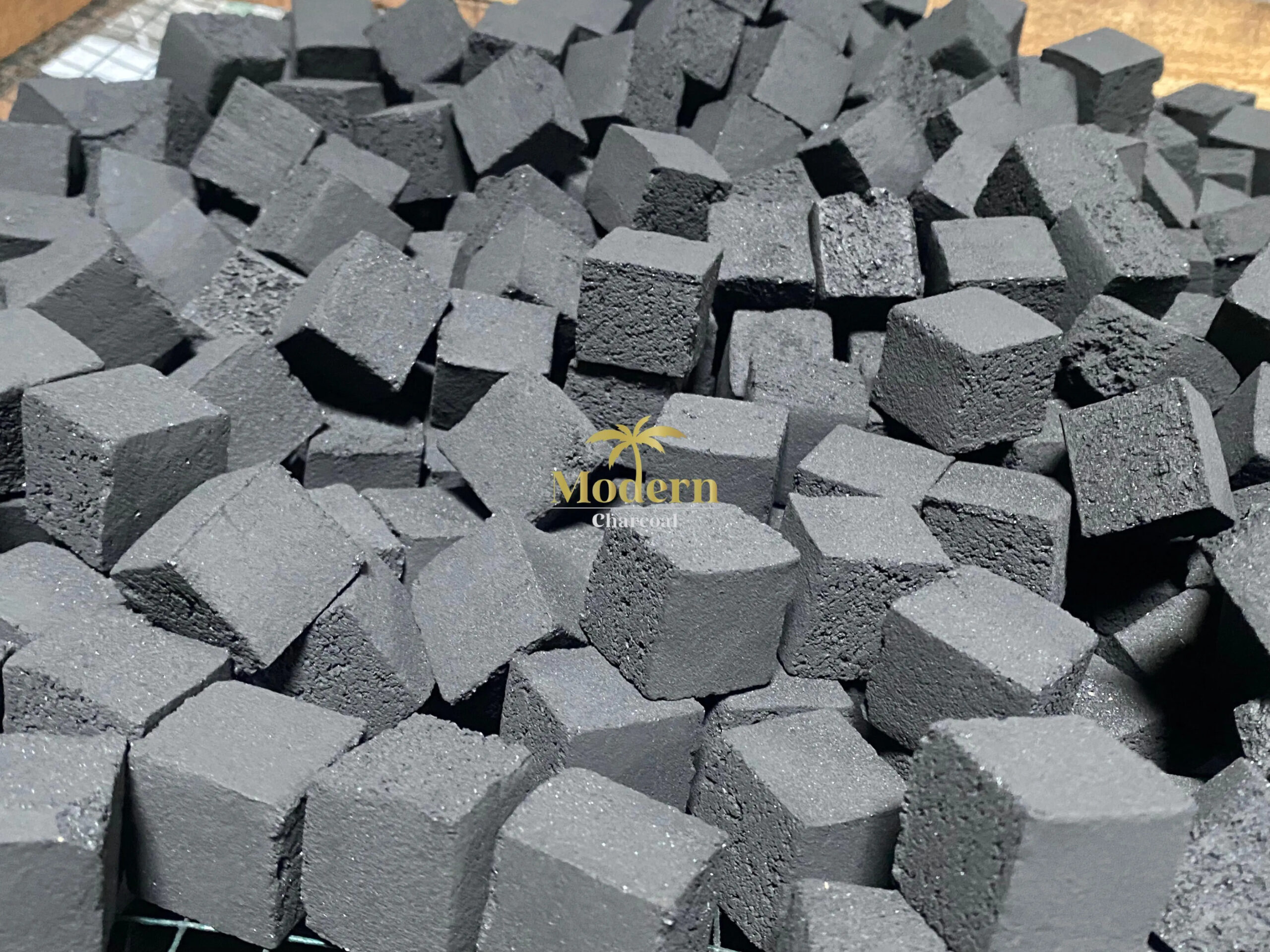

The charcoal and binder mixture is then compressed into briquettes. This can be done using a manual or mechanical press. The shape and size of the briquettes can vary, depending on the intended use and the preferences of the maker.

5. Drying

Finally, the formed briquettes are left to dry in a well-ventilated area. This step solidifies the briquettes and prepares them for burning. The drying process can take from a few days to a week, depending on the climate and the moisture content of the briquettes.

Environmental and Social Benefits

The production of charcoal briquettes from natural ingredients offers numerous environmental and social benefits. It provides a sustainable way to manage agricultural and forestry waste, reducing landfill waste and the emission of greenhouse gases. Additionally, it creates opportunities for local communities, especially in rural areas, where the materials are readily available, and the demand for clean, affordable fuel is high.

Embracing the Future with Ancient Wisdom

The art of crafting charcoal briquettes from natural ingredients is a shining example of how traditional knowledge and modern needs can converge to create sustainable solutions. By embracing these practices, we can reduce our environmental footprint, support local economies, and move towards a more sustainable and resilient future.

Coconut charcoal briquettes are a type of charcoal made from the shells of coconuts, offering an eco-friendly alternative to traditional wood charcoal. This innovative product capitalizes on the abundance of coconut shells, turning what would otherwise be waste into a valuable resource for cooking and heating.

As we continue to explore and innovate, let us remember the value of harnessing nature’s bounty. The crafting of charcoal briquettes from natural ingredients is not just an art; it’s a testament to our ability to live in harmony with the environment, proving that sometimes, the best way forward is by looking back.

In conclusion, the crafting of best charcoal briquettes from natural ingredients is more than just a method of producing sustainable fuel; it is a holistic approach that embraces the principles of circular economy and environmental sustainability. It showcases how, by harnessing nature’s bounty thoughtfully and innovatively, we can address some of the most pressing environmental challenges while also paving the way for a greener, more sustainable future. This endeavor not only highlights the potential of natural ingredients in creating valuable resources but also serves as a beacon for eco-conscious living and sustainable development worldwide.