Charcoal briquettes have become a staple for outdoor grilling and barbecue, offering a consistent and manageable heat source that can transform the cooking experience. But beyond their practical applications, the composition and production process of charcoal briquettes are subjects of interest in themselves, revealing a complex blend of science, sustainability, and engineering. This article delves into what charcoal briquettes are made of, exploring their ingredients, production process, and environmental considerations.

Ingredients of Charcoal Briquettes

The primary ingredient of charcoal briquettes is charcoal, which is produced by burning wood in the absence of oxygen. This process, known as pyrolysis, removes water and volatile compounds from the wood, leaving behind a high-carbon content product known as charcoal. However, charcoal alone does not make a briquette. Several other components are added to bind the charcoal and help it ignite and burn more efficiently:

1. Binders: Binders are crucial in forming the charcoal into briquettes. They help hold the charcoal powder together, giving the briquettes their shape and ensuring they do not crumble. Common binders include starch, which is often derived from corn, wheat, or potato, and natural gums. Some manufacturers may use chemical binders, but there is a growing trend towards using natural, biodegradable binders for environmental reasons.

2. Fillers: Fillers are used to increase the volume of the briquettes and can affect the burning properties. They are typically made from cheap and combustible materials like sawdust, wood chips, and even coal dust. The choice of filler can influence the heat output and burn time of the briquettes.

3. Ignition Aids: To help the briquettes light more easily, manufacturers may add substances that catch fire quickly. These can include nitrates, which also help the briquettes burn more evenly and consistently.

4. Moisture and Ash Whiteners: A small amount of moisture is necessary to help the binder work effectively, while ash whiteners, like lime, are added to ensure that the briquettes produce a visually appealing ash when burned.

Production Process

The production of charcoal briquettes involves several key steps:

1. Charcoal Making: Wood or other biomass is burned in a low-oxygen environment to produce charcoal.

2. Crushing and Mixing: The charcoal is then crushed into a fine powder and mixed with the binders, fillers, and any other additives.

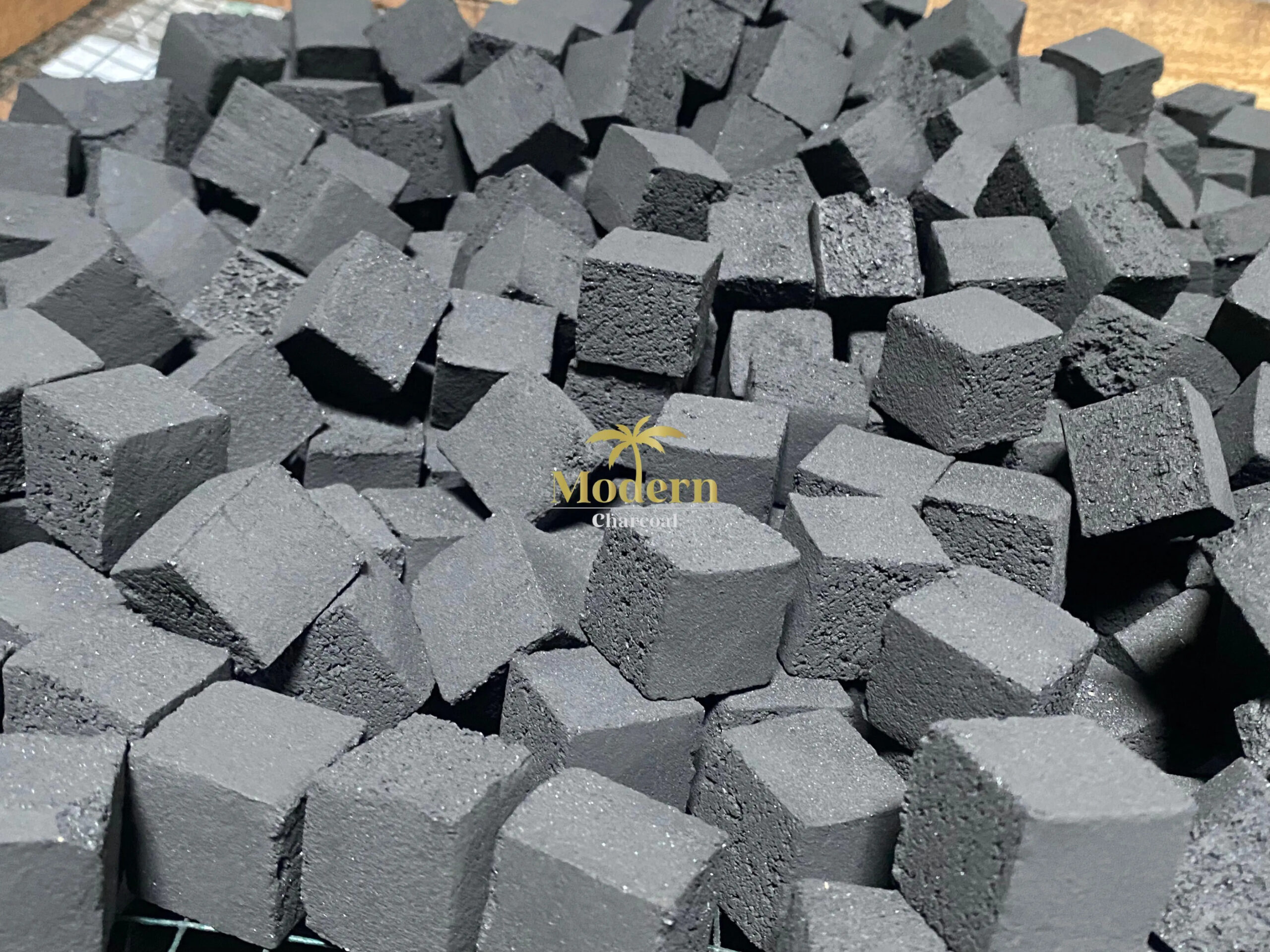

3. Shaping: The mixture is then pressed into molds, forming the briquettes. This can be done using a variety of methods, from simple hand presses to sophisticated industrial machinery.

4. Drying: The formed briquettes are dried to remove excess moisture, ensuring they are ready to be packaged and sold.

Environmental Considerations

The environmental impact of charcoal briquettes is a topic of considerable debate. On the one hand, they offer a more efficient and cleaner-burning alternative to traditional lump charcoal, with fewer emissions and a more consistent heat output. On the other hand, concerns about deforestation and the carbon footprint associated with charcoal production have prompted a search for more sustainable ingredients and production methods. Some companies are now producing briquettes from renewable sources like coconut shells, bamboo, and recycled sawdust, aiming to reduce the environmental impact.

Conclusion

Charcoal briquettes are more than just a convenient fuel for barbecue enthusiasts; they are the product of a complex blend of materials and processes designed to deliver a consistent, efficient, and enjoyable cooking experience. Understanding what goes into them not only enhances our appreciation of this humble cooking fuel but also highlights the importance of pursuing sustainable practices in their production. As we continue to enjoy the benefits of charcoal briquettes, it’s crucial to support innovations that minimize their environmental impact, ensuring that future generations can continue to grill sustainably.